Commercial building spray foam envelope serves as the primary defense system for any structure, physically separating the conditioned interior environment from the unconditioned exterior. It controls the flow of heat, air, and moisture, determining how hard your heating and cooling systems must work. A high-performance envelope prevents energy waste by sealing air leaks and providing thermal resistance, resulting in lower utility bills and consistent indoor comfort.

Managing energy costs starts with the building envelope, not the mechanical systems inside. Over years of diagnosing comfort issues in Austin, experience shows that upgrading an HVAC unit without addressing a leaky envelope yields minimal gains. High-efficiency equipment cannot compensate for a home that continuously bleeds conditioned air.

The Mechanics of Heat Transfer and Airflow

To understand energy efficiency, you must understand how heat moves. Heat naturally flows from warmer areas to cooler ones. In the summer, outside heat pushes its way inside; in the winter, interior heat tries to escape. The building envelope slows this process through thermal resistance, commonly measured as R-value.

Air leakage complicates this dynamic. Small cracks, gaps, and holes allow conditioned air to escape and unconditioned air to enter. This phenomenon, often driven by the “stack effect,” forces your HVAC system to run longer cycles to maintain the set temperature. Data published by Energy Star indicates that homeowners can save an average of 15% on heating and cooling costs simply by air sealing their homes and adding insulation in attics, floors over crawl spaces, and accessible basement rim joists. Furthermore, this lack of control impacts more than just your wallet; the EPA states that controlling air flow is fundamental to managing indoor air quality and preventing the infiltration of outdoor pollutants and allergens.

Thermal Bridging

Insulation alone does not guarantee efficiency if the structural framing creates thermal bridges. Wood and metal studs transfer heat faster than the insulation between them. A comprehensive envelope strategy accounts for these bridges, often by adding continuous insulation over the framing or selecting materials that seal around the studs. As described by the Building Science Corporation, the most effective wall assemblies, often termed “perfect walls,” prioritize continuous control layers to eliminate thermal bridges and ensure long-term performance.

Key Components of a High-Performance Envelope

A functional building envelope relies on three main control layers working in unison: the air barrier, the thermal barrier, and the vapor retarder.

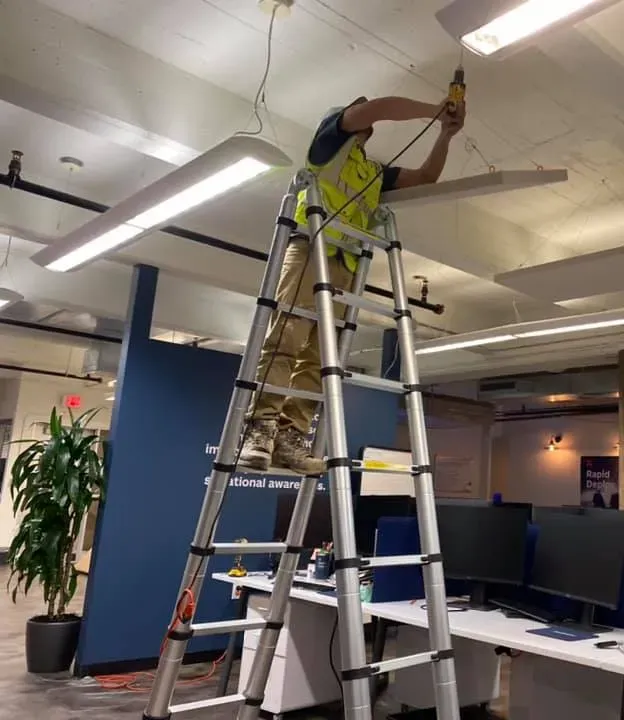

- Air Barrier: This blocks random air movement through the building cavities. Materials like spray foam, house wrap, and caulk form this line of defense.

- Thermal Barrier: This slows the flow of conductive heat. Common materials include fiberglass, cellulose, and rigid foam board.

- Glazing (Windows and Doors): Glass acts as a hole in the insulated wall. High-performance glazing uses low-emissivity (Low-E) coatings and multiple panes to reduce heat transfer.

Bonus Tip: Pay close attention to recessed lighting fixtures and plumbing penetrations. These are common failure points in the air barrier where significant energy loss occurs.

Comparing Insulation Materials

Choosing the right material impacts both the thermal and air barriers. The following table compares common insulation solutions based on their ability to resist heat flow and stop air movement.

| Material Type | Approximate R-Value per Inch | Air Sealing Capability | Moisture Resistance | Best Application |

|---|---|---|---|---|

| Open Cell Spray Foam | R-3.5 to R-3.8 | Excellent | Moderate (Permeable) | Attics, Walls, Roof Decks |

| Closed Cell Spray Foam | R-6.0 to R-7.0 | Superior | High (Vapor Barrier) | Basements, Exterior Walls |

| Fiberglass Batts | R-2.9 to R-3.8 | Poor | Low | Stud Cavities (Dry Areas) |

| Blown-in Cellulose | R-3.1 to R-3.8 | Fair (Dense Packed) | Moderate | Attics, Retrofit Walls |

Moisture Control and Structural Durability

Energy efficiency connects directly to building durability. Air movement carries moisture. When warm, moist air leaks into a wall cavity and hits a cold surface, condensation forms. This leads to mold growth, wood rot, and degraded insulation performance. Wet insulation loses its ability to resist heat flow, rendering the R-value useless.

According to the Department of Energy, controlling moisture accumulation is vital to preserving the building’s structural integrity. A proper envelope design keeps water out and allows any moisture that does get in to dry to the exterior or interior, depending on the climate.

Things to Consider Before Making a Decision

Before investing in envelope upgrades, evaluate the building’s current condition.

- Conduct a Blower Door Test: This diagnostic test quantifies air leakage. It reveals exactly how much air is entering the home and helps pinpoint the leaks.

- Identify Your Climate Zone: The strategy for a building in a hot, humid climate differs from that for a building in a cold, dry climate. In hot climates, the vapor barrier is usually on the exterior; in cold climates, it is often on the interior.

- Analyze the Return on Investment (ROI): While high-performance materials like spray foam may cost more upfront, the monthly energy savings and extended HVAC equipment life often provide a better long-term return than cheaper alternatives.

Bonus Tip: Prioritize the attic and the foundation (rim joist) first. These areas typically experience the highest pressure differentials and account for the most significant air leakage.

Summary and Next Steps

A robust building envelope is the foundation of energy efficiency. By controlling heat transfer and eliminating air leaks, you reduce the load on mechanical systems and protect the structure from moisture damage. Before purchasing a new HVAC system or replacing windows, evaluate the airtightness and insulation levels of your property. Addressing the envelope first ensures that every dollar spent on heating and cooling stays inside the building.

Ready to Secure Your Building Envelope?

Stop paying to heat and cool the outdoors. Stellrr Insulation & Spray Foam can diagnose your building’s weak points and implement a solution that permanently lowers your energy usage.

Contact us today to schedule your assessment:

Phone: (512) 710-2839 Email: info@stellrr.com

Frequently Asked Questions

How long does an envelope upgrade typically take?

Most residential retrofit projects, such as attic air sealing and insulation, take one to two days. Larger projects involving wall injection or crawlspace encapsulation may take three to four days, depending on the square footage.

Does upgrading the envelope help with noise?

Yes. The same gaps that let air through also let sound through. Materials like spray foam and dense-packed cellulose significantly dampen outside noise, making the interior environment quieter.

Do I need to remove the old insulation before adding new insulation?

In many cases, yes. If rodents, water, or mold damage the existing insulation, it must be removed to sanitize the area and properly air-seal the surface. Putting new material over damaged material hides the problem rather than solving it.

What is the most critical area to seal in an existing home?

The top plate in the attic. This is where the ceiling drywall meets the wall framing. It is a significant source of air leakage in almost every home built before the mid-2000s.

Sources

- Energy Star – Methodology for estimated energy savings from sealing and insulating.

- EPA – Overview of Indoor Air Quality and how controlling airflow prevents pollutant infiltration.

- Building Science Corporation – Insights on “The Perfect Wall” concept and the importance of continuous control layers.

- Department of Energy – Information on moisture control and its impact on energy efficiency and building health.